N2 Injection Unit

Features

Datasheet

N2 Cryogenic Thermos

Features

Datasheet

Pipelines (Surface Control Lines)

Features

The Surface Control Lines for work that are carried out in onshore and offshore wells require the pipelines interconnection to be able to flow or transfer fluids of different types into or out of the well.

Datasheet

RCD'S

Features

Rotary Heads Equipment Capacity

Datasheet

MPD SEMCCO System

Features

Single high-pressure units

Features

Datasheet

Double high-pressure units

Features

Datasheet

Baskets and diesel tanks

Features

Datasheet

Cutting Box

Features

Datasheet

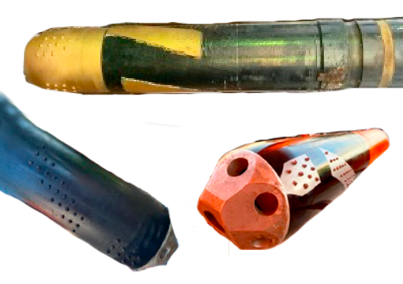

REAMER SHOES

Features

CASING BITS

Features

FLOAT EQUIPMENTS

Features

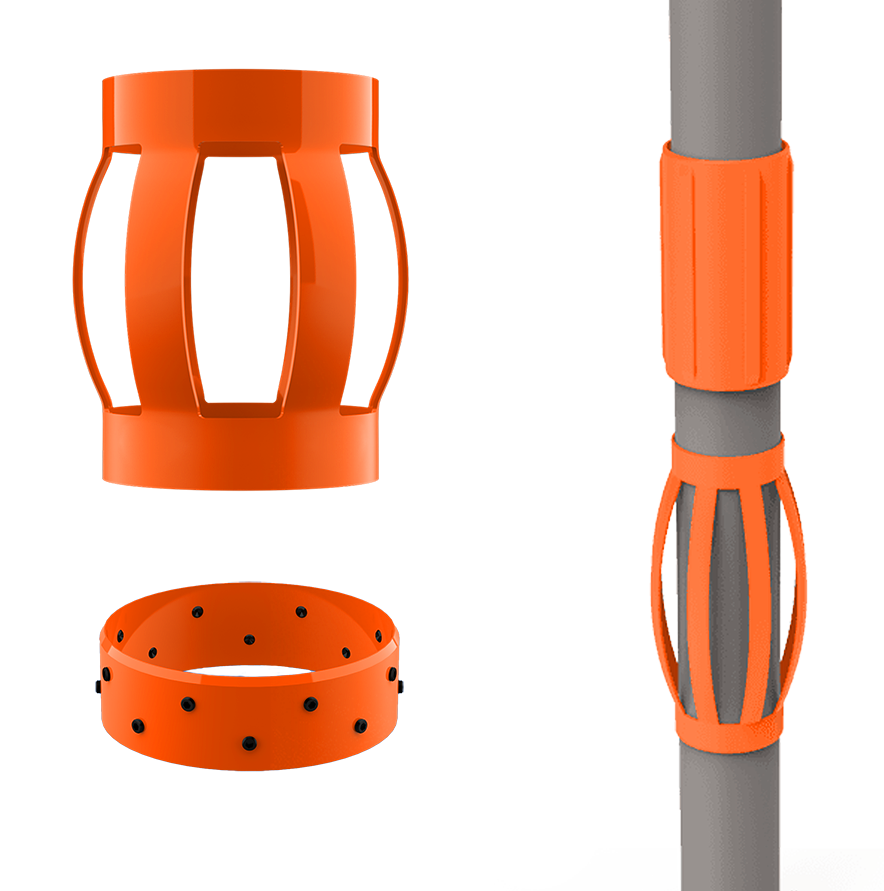

CENTRALIZERS AND COLLARS

Features

| ÍTEM | TYPE | NOM OD | LBS/FT | STEEL GRADE | CONNECTION |

|---|---|---|---|---|---|

| 1 | SHOE FLOAT STAB IN | 30 | 264.87 | X-42 | DRILL QUIP |

| 2 | SHOE FLOAT | 30 | 264.87 | X-42 | BUTT WELD |

| 3 | SHOE FLOAT | 30 | 264.87 | X-42 | DRILL QUIP |

| 4 | SHOE FLOAT | 30 | 310 | X-52 | BUTT WELD |

| 5 | SHOE FLOAT RPT REAMER | 20 | 94 | K-55 | BUTTRESS |

| 6 | COLLAR SFBB | 20 | 94 | K-55 | BUTTRESS |

| 7 | SHOE FLOAT RPT REAMER | 20 | 94 | K-55 | TSH ER |

| 8 | COLLAR SFBB | 20 | 94 | K-55 | TSH ER |

| 9 | SHOE FLOAT RPT REAMER | 20 | 94 | K-55 | DRILL QUIP |

| 10 | COLLAR SFBB | 20 | 94 | K-55 | DRILL QUIP |

| 11 | SHOE FLOAT RPT REAMER | 20 | 133 | K-55 | DRILL QUIP |

| 12 | COLLAR SFBB | 20 | 133 | K-55 | DRILL QUIP |

| 13 | SHOE FLOAT RPT REAMER | 20 | 133 | X-52 | TSH ER |

| 14 | COLLAR SFBB | 20 | 133 | X-52 | TSH ER |

| 15 | SHOE FLOAT RPT REAMER | 20 | 133 | K-55 | TSH ER |

| 16 | COLLAR SFBB | 20 | 133 | K-55 | TSH ER |

| 17 | PLUG | 20 | N/A | N/A | N/A |

| 18 | PLUG | 20 | N/A | N/A | N/A |

| 19 | COLLAR FLOAT | 20 | 147 | K-55 | TSH ER |

| 20 | COLLAR SFBB | 20 | 129.33 | X-52 | TSH ER |

| 21 | SHOE FLOAT RPT REAMER | 20 | 133 | X-52 | DRILL QUIP |

| 22 | COLLAR SFBB | 20 | 133 | X-52 | DRILL QUIP |

| 23 | COLLAR SFBB | 16 | 109 | P-110 | TSH 521 |

| 24 | PLUG | 16 | N/A | N/A | N/A |

| 25 | PLUG | 16 | N/A | N/A | N/A |

| 26 | SHOE FLOAT RPT REAMER | 16 | 109 | P-110 | TSH 521 |

| 27 | COLLAR SFBB | 16 | 109 | P-110 | VAM LIFT |

| 28 | COLLAR SFBB | 14 | 113 | P-110 | TSH 513 |

| 29 | SHOE GUIDE SFBB | 14 | 113 | P-110 | TSH 513 |

| 30 | SHOE FLOAT RPT REAMER | 13.625 | 88.2 | TAC-110 | TSH 523 |

| 31 | SHOE FLOAT RPT REAMER | 13.625 | 88.2 | TAC-110 | TSH 521 |

| 32 | COLLAR SFBB | 13.625 | 88.2 | TAC-110 | TSH 521 |

| 33 | SHOE FLOAT RPT REAMER | 13.625 | 88.2 | TAC-140 | TSH 521 |

| 34 | COLLAR SFBB | 13.625 | 88.2 | TAC-140 | TSH 521 |

| 35 | SHOE FLOAT RPT REAMER | 13.625 | 88.2 | TAC-140 | TSH 523 |

| 36 | COLLAR SFBB | 13.625 | 88.2 | TAC-140 | TSH 523 |

| 37 | PLUG | 13.625 | N/A | N/A | N/A |

| 38 | PLUG | 13.625 | N/A | N/A | N/A |

| 39 | COLLAR SFBB | 13.625 | 88.2 | P-110 | TSH 523 |

| 40 | SHOE GUIDE | 13.625 | 88.2 | P-110 | TSH 523 |

| 41 | SHOE FLOAT RPT REAMER | 13.375 | 72 | TAC-110 | TSH 521 |

| 42 | SHOE FLOAT RPT REAMER | 13.375 | 72 | TAC-140 | TSH 521 |

| 43 | COLLAR SFBB | 13.375 | 72 | TAC-140 | TSH 521 |

| 44 | SHOE FLOAT RPT REAMER | 13.375 | 72 | P-110 | TSH 521 |

| 45 | COLLAR SFBB | 13.375 | 72 | P-110 | TSH 521 |

| 46 | COLLAR SFBB | 13.375 | 72 | L-80 | TSH 521 |

| 47 | COLLAR SFBB | 13.375 | 68 | P-110 | TSH 521 |

| 48 | SHOE GUIDE | 13.375 | 68 | L-80 | TSH 521 |

| 49 | SHOE FLOAT RPT REAMER | 13.375 | 68 | L-80 | TSH 521 |

| 50 | COLLAR SFBB | 13.375 | 68 | P-110 | TSH 523 |

| 51 | SHOE FLOAT RPT REAMER | 11.75 | 65 | TAC-140 | TSH 523 |

| 52 | COLLAR SFBB | 11.75 | 65 | TAC-140 | TSH 523 |

| 53 | SHOE FLOAT RPT REAMER | 11.75 | 65 | P-110 | TSH 521 |

| 54 | COLLAR SFBB | 11.75 | 65 | P-110 | TSH 521 |

| 55 | PLUG | 11.75 | N/A | N/A | N/A |

| 56 | PLUG | 11.75 | N/A | N/A | N/A |

| 57 | COLLAR SFBB | 11.75 | 65 | TAC-110 | TSH 523 |

| 58 | COLLAR LANDING | 11.75 | 65 | TAC-140 | TSH 523 |

| 59 | PLUG | 11.75 | N/A | N/A | N/A |

| 60 | SHOE FLOAT RPT REAMER | 10.25 | 79.29 | TAC-140 | TSH 523 |

| 61 | COLLAR SFBB | 10.25 | 79.29 | TAC-140 | TSH 523 |

| 62 | COLLAR LANDING | 10.25 | 79.29 | TAC-140 | TSH 523 |

| 63 | COLLAR SFBB | 10.25 | 79.29 | Q-125 | TSH 523 |

| 64 | PLUG | 9.875 | N/A | N/A | N/A |

| 65 | SHOE FLOAT RPT REAMER | 9.875 | 62.8 | TAC-140 | TSH 523 |

| 66 | COLLAR SFBB | 9.875 | 62.8 | TAC-140 | TSH 523 |

| 67 | COLLAR LANDING | 9.875 | 62.8 | TAC-140 | TSH 523 |

| 68 | COLLAR FLOAT ORIFICE | 9.875 | 62.8 | TAC-140 | TSH 523 |

| 69 | PLUG | 9.875 | N/A | N/A | N/A |

| 70 | PLUG | 9.875 | N/A | N/A | N/A |

| 71 | COLLAR FLOAT ORIFICE | 9.875 | 62.8 | TAC-140 | VAM SLIJ-II |

| 72 | COLLAR SFBB | 9.875 | 62.8 | TAC-140 | VAM SLIJ-II |

| 73 | PLUG | 9.625 | N/A | N/A | N/A |

| 74 | PLUG | 9.625 | N/A | N/A | N/A |

| 75 | SHOE FLOAT RPT REAMER | 9.625 | 53.5 | TAC-140 | TSH 523 |

| 76 | COLLAR SFBB | 9.625 | 53.5 | TAC-140 | TSH 523 |

| 77 | SHOE FLOAT RPT REAMER | 9.625 | 53.5 | TAC-140 | VAM SLIJ-II |

| 78 | COLLAR SFBB | 9.625 | 53.5 | TAC-140 | VAM SLIJ-II |

| 79 | SHOE FLOAT RPT REAMER | 9.625 | 53.5 | P-110 | VAM SLIJ-II |

| 80 | COLLAR FLOAT ORIFICE | 9.625 | 53.5 | P-110 | VAM SLIJ-II |

| 81 | SHOE FLOAT RPT REAMER | 9.625 | 53.5 | P-110 | TSH 523 |

| 82 | COLLAR SFBB | 9.625 | 53.5 | P-110 | TSH 523 |

| 83 | SHOE FLOAT RPT REAMER | 9.625 | 53.5 | L-80 | TSH 523 |

| 84 | COLLAR SFBB | 9.625 | 53.5 | L-80 | TSH 523 |

| 85 | SHOE FLOAT RPT REAMER | 9.625 | 53.5 | L-80 | VAM SLIJ-II |

| 86 | COLLAR SFBB | 9.625 | 53.5 | L-80 | VAM SLIJ-II |

| 87 | COLLAR FLOAT | 9.625 | 36-40 | K-55 | BUTTRESS |

| 88 | COLLAR FLOAT ORIFICE | 9.625 | 53.5 | P-110 | TSH 523 |

| 89 | COLLAR FLOAT ORIFICE | 9.625 | 53.5 | TAC-140 | VAM SLIJ-II |

| 90 | COLLAR FLOAT ORIFICE | 9.625 | 53.5 | TAC-140 | TSH 523 |

| 91 | SHOE FLOAT RPT REAMER | 7.75 | 54.2 | TAC-140 | TSH 623 |

| 92 | COLLAR SFBB | 7.75 | 54.2 | TAC-140 | TSH 623 |

| 93 | SHOE GUIDE | 7.625 | 39 | P-110 | VAM SLIJ-II |

| 94 | SHOE FLOAT RPT REAMER | 7.625 | 39 | P-110 | TSH 513 |

| 95 | PLUG | 7.625 | N/A | N/A | N/A |

| 96 | PLUG | 7.625 | N/A | N/A | N/A |

| 97 | SHOE FLOAT RPT REAMER | 7 | 29 | P-110 | TSH 563 |

| 98 | COLLAR SFBB | 7 | 29 | P-110 | TSH 563 |

| 99 | SHOE FLOAT RPT REAMER | 7 | 38 | TAC-140 | TSH 513 |

| 100 | COLLAR SFBB | 7 | 38 | TAC-140 | TSH 513 |

| 101 | SHOE FLOAT RPT REAMER | 7 | 42.7 | TAC-140 | TSH 563 |

| 102 | COLLAR SFBB | 7 | 42.7 | TAC-140 | TSH 563 |

| 103 | SHOE FLOAT RPT REAMER | 7 | 35 | TAC-140 | TSH 513 |

| 104 | COLLAR SFBB | 7 | 35 | TAC-140 | TSH 513 |

| 105 | COLLAR FLOAT ORIFICE | 7 | 38 | TAC-140 | VAM SLIJ-II |

| 106 | COLLAR FLOAT ORIFICE | 7 | 38 | TAC-140 | TSH 523 |

| 107 | SHOE FLOAT | 7 | N/D | K-55 | LG 8RD |

| 108 | COLLAR FLOAT | 7 | N/D | K-55 | LG 8RD |

| 109 | PLUG | 7 | N/A | N/A | N/A |

| 110 | PLUG | 7 | N/A | N/A | N/A |

| 111 | COLLAR SFBB | 7 | 29 | L-80 | VAM TOP |

| 112 | SHOE FLOAT RPT REAMER | 7 | 42.7 | TAC-140 | VAM SLIJ-II |

| 113 | COLLAR SFBB | 7 | 42.7 | TAC-140 | VAM SLIJ-II |

| 114 | SHOE FLOAT RPT REAMER | 7 | 29 | L-80 | TSH 523 |

| 115 | COLLAR SFBB | 7 | 29 | L-80 | TSH 523 |

| 116 | COLLAR LANDING | 7 | 35 | TAC-140 | TSH 513 |

| 117 | SHOE GUIDE | 5.5 | 23 | P-110 | VAM SLIJ-II |

| 118 | SHOE FLOAT RPT REAMER | 5 | 21.4 | TAC-140 | TSH 513 |

| 119 | COLLAR SFBB | 5 | 21.4 | TAC-140 | TSH 513 |

| 120 | SHOE FLOAT RPT REAMER | 5 | 21.4 | TAC-140 | VAM SLIJ-II |

| 121 | COLLAR SFBB | 5 | 21.4 | TAC-140 | VAM SLIJ-II |

| 122 | SHOE FLOAT RPT REAMER | 5 | 18 | TAC-140 | TSH 513 |

| 123 | COLLAR SFBB | 5 | 18 | TAC-140 | TSH 513 |

| 124 | SHOE FLOAT RPT REAMER | 5 | 18 | TAC-140 | VAM SLIJ-II |

| 125 | COLLAR SFBB | 5 | 18 | TAC-140 | VAM SLIJ-II |

| 126 | SHOE FLOAT RPT REAMER | 5 | 21.4 | TAC-140 | VAM FJL |

| 127 | SHOE FLOAT RPT REAMER | 5 | 18 | P-110 | TSH 513 |

| 128 | INNER STRING ADAPTER | 1 | N/A | N/A | 5 1/2 API FH |

| 129 | CENTRALIZER for INNER STRING | 1 | N/A | N/A | N/A |